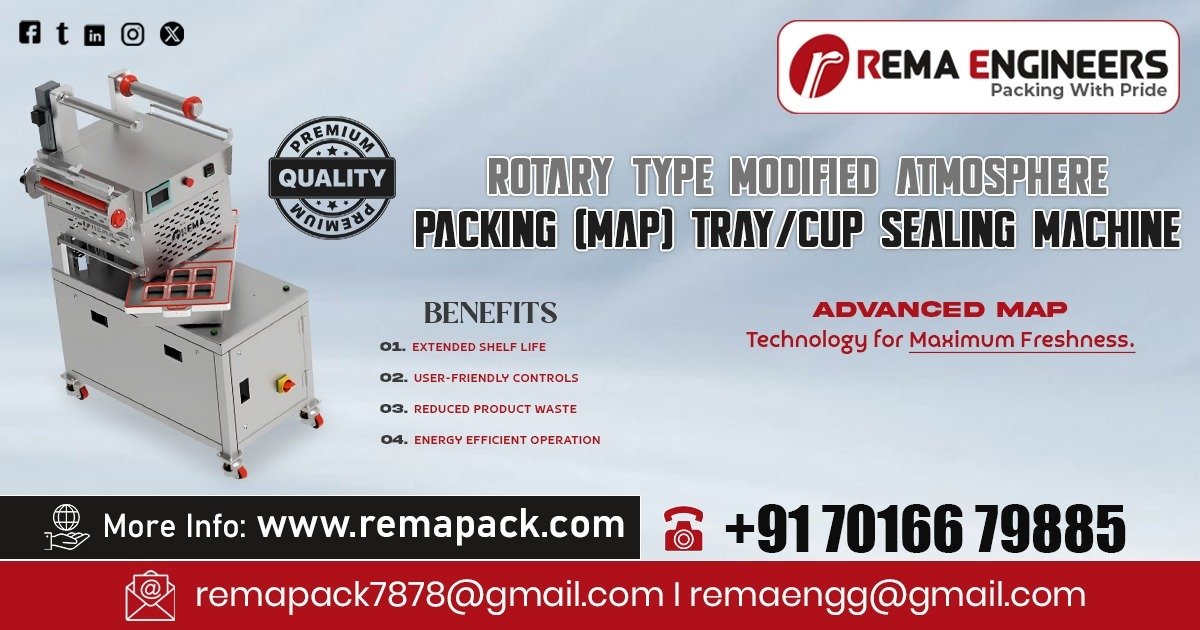

Rema Engineers is a leading Manufacturer and Supplier of Rotary MAP (Vacuum+Gas) Tray Sealing Machine in Karnataka, India.

The Rotary MAP Tray Sealing Machine by Rema Engineers enhances packaging standards across pharmaceuticals, FMCG, and food industries.

Combining advanced vacuum and gas flushing technologies, the machine ensures longer shelf life, product freshness, and packaging consistency.

Its rotary configuration provides seamless high-volume processing, guaranteeing efficiency, durability, and reliable performance for industrial-scale packaging applications.

This semi-automatic system modifies tray atmosphere by extracting air and flushing inert gas before achieving precise sealing.

This process safeguards the contents from spoilage, oxidation, and microbial growth—ideal for perishable foods and sensitive products.

Types & Model Details:

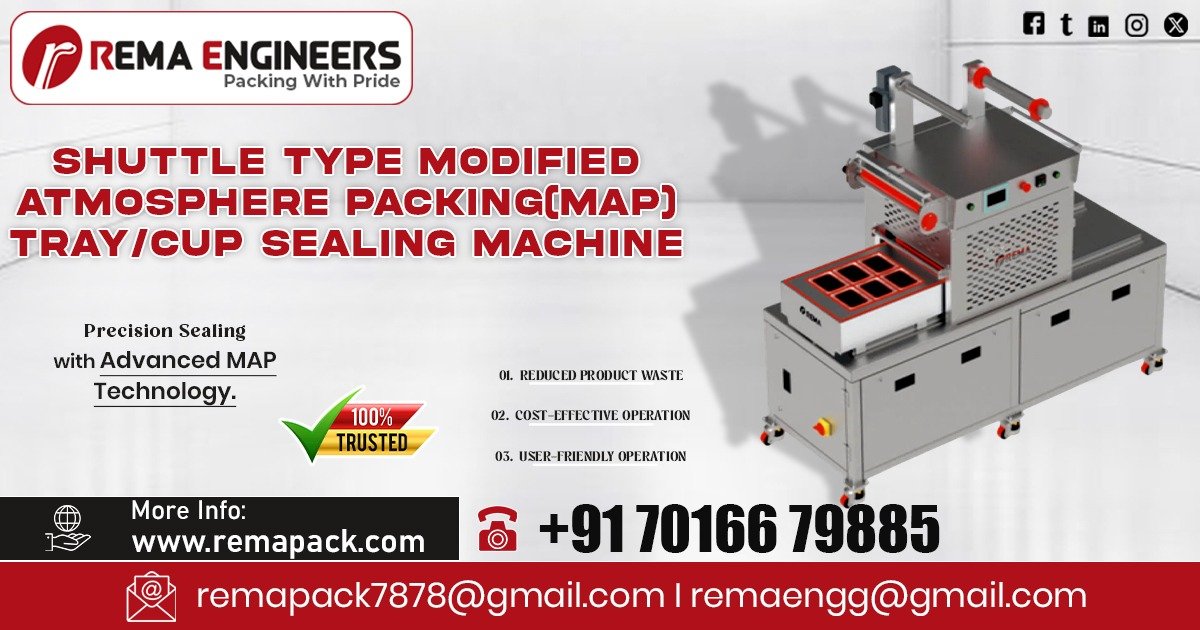

Rema Engineers provides a Rotary Type Semi‑Automatic MAP (Vacuum+Gas) Tray/Cup Sealing Machine, model REMA‑7878‑MAP‑ROTARY. It’s part of a broader product lineup that includes linear, shuttle-type, and fully automated MAP tray sealers.

Features & Specifications:

Specifications (Model REMA‑7878‑MAP‑ROTARY).

Down Chamber Height: 120 mm (adjustable/ customizable).

Max Film Size (W × D): 380 × 350 mm* (customizable).

Control Panel: PLC with HMI (Delta make).

Power Supply: 415 V, 3‑phase, 50 Hz, 3 kW.

Vacuum Pump: Becker (German), achieving 99.50% vacuum.

Cycles per Minute: 3–4 cycles.

Operations Performed: Vacuum + Gas flushing + Sealing + Cutting.

Pneumatic Parts: SMC or Janatics.

Construction: Aluminum or Stainless Steel 304.

Weight & Dimensions: Approximately 500 kg; 1200 × 1200 × 1400 mm.

Gas Flush: Yes.

Compressed Air Requirement: 6–7 kg/cm² (provided by client).

Features & Benefits:

Semi-auto rotary mechanism ensures continuous, efficient workflow.

Accurate vacuum and gas flushing—produces minimal residual oxygen (< 0.5%), extending product shelf life.

Fast tray mold changeover (< 3 minutes).

Touchscreen recipe settings for versatility.

Easy-to-clean, rust-resistant materials: SS 304, cast aluminum.

Short cycle times boost throughput and productivity.

Applications:

Ideal for packaging perishable or delicate goods, including:

Sweets, desserts, dry fruits, cheese, bakery items, snacks

Fresh fruits & vegetables, meats, seafood, ready-to-eat foods

Sauces, confectioneries, jellies, and more.

Rema Engineers is a leading Manufacturer and Supplier of Rotary MAP (Vacuum+Gas) Tray Sealing Machine in Karnataka, India Including Badami, Belagavi, Chamarajanagar, Bhadravati, Bidar, Hassan, Bagalkot, Bidar, Chikkamagaluru, Kalaburagi, Kolar, Ballari, Belagavi, Bangalore, Dakshina Kannada, Haveri, Kodagu, Bengaluru, Davangere, Halebid, Hassan, Hubballi-Dharwad, Kalaburagi, Kolar, Madikeri, Mandya, Mangaluru, Urban, Chitradurga, Vijayapura, Gadag, Tumakuru, Bangalore, Mysuru, Raichur, Shivamogga, Shravanabelagola, Shrirangapattana, Ramanagara, Kittur.

For further inquiries or customized solutions, feel free to contact us.