The Semi-Automatic MAP (Vacuum + Gas) Tray/Cup Sealing Machine from Rema Engineers is an advanced and reliable solution for packaging products that require extended shelf life and optimal freshness. This machine utilizes a combination of vacuum and gas flushing technologies to remove air and replace it with a tailored gas mixture, ensuring the perfect modified atmosphere for each product.

Semi Automatic MAP (Vacuum + Gas)

Tray/Cup Sealing Machine

Home » Products & solutions » Semi Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine » Semi Automatic MAP (Vacuum + Gas) Tray/Cup Sealing Machine

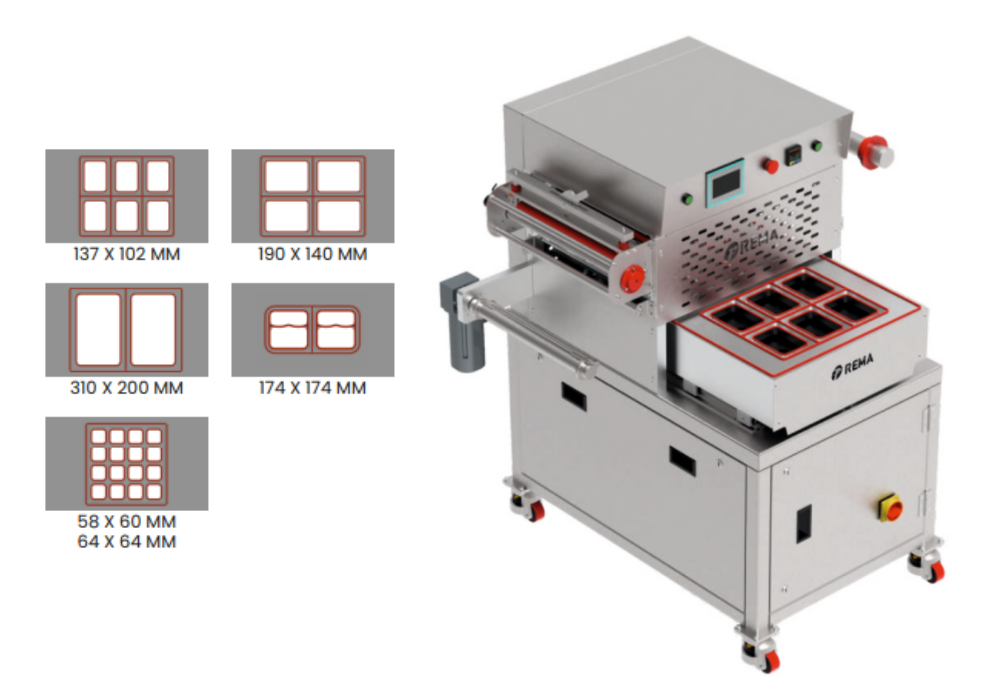

Designed for flexibility and efficiency, this semi-automatic machine offers precise control over both the vacuum and gas flushing processes, allowing operators to customize the packaging to meet specific requirements. It handles a variety of tray and cup sizes, making it a versatile solution for businesses with diverse packaging needs. The machine’s user-friendly interface ensures ease of operation, while its robust construction ensures durability and long-lasting performance. With Rema Engineers’ focus on quality and innovation, the MAP (Vacuum + Gas) Tray/Cup Sealing Machine is an ideal choice for companies looking to improve their packaging process, enhance product quality, and reduce waste while maintaining cost-effectiveness.

- Standard Features & Benefits:

- Semi Auto MAP Tray Sealing Machine Suitable for standard trays & Cups.

- Accurate Vacuum & Gas Flushing Systems.

- Products can be pack Sweets/Desserts, Dry fruits, Cheese, Fresh Fruits & Vegetables, Bakery, Snacks, Meat/Sea Foods, Ready to Eat Foods, Sauces, Confectionery-Jellies Etc.

- Stainless Steel Body, cast aluminum & non-ferrous material to safe rust issues and easy cleaning.

- Longer shelf life of food due to extremely low oxygen residual (< 0,5%)

- Fast exchangeable tray mould (< 3 minutes)

- Short cycle time (2 Cycles/Min.)

- Touchscreen for easy setting of recipes

- Great presentation of your products

- Optional Features:

- Eye Mark Sensors For Printed Roll.

- Can Be Customize According to Customers Requirements.

- Bottom Chamber Height Can Be Increased Up to 150 mm for Bigger Tray Heights.

- Standard Model Technical Specifications:

| MODEL NO. | REMA-7878-MAP-SEMI-BIG |

|---|---|

| Max. Tray Height | 120 mm ** Can Be Customized It |

| Film Max (W X D) | W 380 mm X 350 mm ** Can Be Customized It |

| No. of Trays Can Be Feed | 250 Gm - 6 Trays, 500 Gm - 4 Trays, 1 Kg - 2 Trays |

| Operations On Trays | Vacuum + Gas Flush + Sealing + Cutting |

| Cycle Per Minute (MAP/only Seal) | 2 Cycle / 4-6 Cycle |

| Control Panel (PLC / HMI) | PLC & Touch Screen HMI Make: Delta |

| Electrical Supply | 415 V AC - 3 Phase - 50 Hz, 5 Kw |

| Vacuum Pump | Busch / Becker Germany |

| Pneumatic Accessories | CKD Japan / Janatics India |

| Vacuum & Gas Sensors | Make: SMC Japan |

| Machine MOC | SS 304 + Aluminium Anodies |

| Machine Dimensions | 1300 mm x 1200 mm x 1350 mm ** |

| Machine Weight | 550 Kg ** |

| Compressed Air Requirements | 6-7 Kg Pressure Require (in Client Scope) |

- our products

- Linear Type Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine

- Shuttle Type Modified Atmosphere Packing(MAP) Tray/Cup Sealing Machine

- Rotary Type Modified Atmosphere Packing (MAP) Tray/Cup Sealing Machine

- Semi Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine

- Fully Automatic VFFS High Speed Pouch Packing Machine

- Servo High Speed Automatic Bag Filling Machines

- Automatic Vacuum Packing Machine

- 2/4 head linear weighing filling machine

- Single Chamber Vacuum Packing Machine

- Double Chamber Vacuum Packing Machine

- Automatic Double Chamber Vacuum Packing Machine (Top Lid – Pneumatic Operated)

- Door Type Vertical Chamber Vacuum Packing Machine

- Vertical Double Chamber Vacuum Packing Machine

- Trolly Type Vertical Chamber Vacuum Packing Machine

- Nozzle Type Chamberless Vacuum Packing Machine

- Thermoforming Vacuum Packing Machine

- download brochure