The Servo Base High Speed Bag Filling Machines from Rema Engineers are designed to offer unparalleled efficiency and precision in high-volume bag filling applications. Built with advanced servo motor technology, these machines ensure faster, more accurate, and consistent filling of various products, including powders, granules, and liquids. The servo-based control system provides precise bag weight control, minimizing errors and reducing product wastage.

Servo High Speed Automatic Bag Filling Machines

Home » Products & solutions » Servo High Speed Automatic Bag Filling Machines

With a user-friendly interface and robust construction, the Servo Base Automatic Bag Filling Machines are engineered for ease of operation and long-lasting durability. They are equipped with state-of-the-art sensors and automatic adjustment features, allowing for seamless integration into your production line. The machines also feature quick-changeover capabilities, enabling fast switching between different bag sizes and product types without compromising on speed or accuracy.

Ideal for industries such as food, chemicals, pharmaceuticals, and more, Rema Engineers’ Servo Base machines are built to handle high-speed operations while maintaining product integrity and minimizing downtime. These machines are an excellent choice for businesses seeking to enhance their production efficiency and meet growing market demands with top-tier technology and reliability.

- Standard Features:

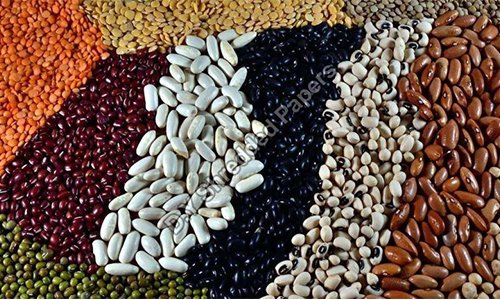

- The REMA MAKE Automatic High Speed Bag Filling Machines designed for industrial applications that deal with granular products like rice, pulses, animal feed, maize, soybeans, seeds, plastic granules, etc. for filling and Stitching/Sealing Bag.

- The accuracy range of the REMA Automatic Bag Filling System is ±5gm up to 5kg, ±10gm up to 25kg, ±20 g up to 50 kg and ±50 g up to 100 kg.

- The speed range of the REMA Automatic Bag Filling System is up to 14 bags per minute for 25kg bagging.

- The filling mode of the REMA Automatic Bag Filling System is with a Servo motor with three stages of feeding, course, moderate, and fine.

- The communication interfaces available with the REMA Automatic Bag Filling System are USB, RS232/485, and Modbus TCP/IP.

- The food contacting material used in the construction of the REMA Automatic Bag Filling System is SS304 stainless steel, and the others are MS.

- The operating temperature range of the REMA Automatic Bag Filling System is 0°C~40°C.

- The power requirement of the REMA Automatic Bag Filling System is 3 phase, AC 110 ~ 260V.50/60Hz. Approximate 200VA.

- The controller used in the Prompt Automatic Bag Filling System is a touch screen bagging controller

- The hardware used in the REMA Automatic Bag Filling System includes a 10-inch touch screen, actuator, F301 mainboard, and 4G signal transmitter (optional), SERVO Motor, Pneumatics etc.

- The benefits of using the REMA Automatic Bag Filling System include Servo base high-speed and accuracy with auto feedback control, easy and fast installation, customization for different materials, user-friendly touch screen, and efficient.

- Increased efficiency, consistency, and reduced labour costs.

- Optional Features:

- Double thread, Auto Thread Cutter Stitching Machine Heat sealing Machine.

- Material Feeding: Z type bucket Elevators or Incline Cleated Belt Conveyor.

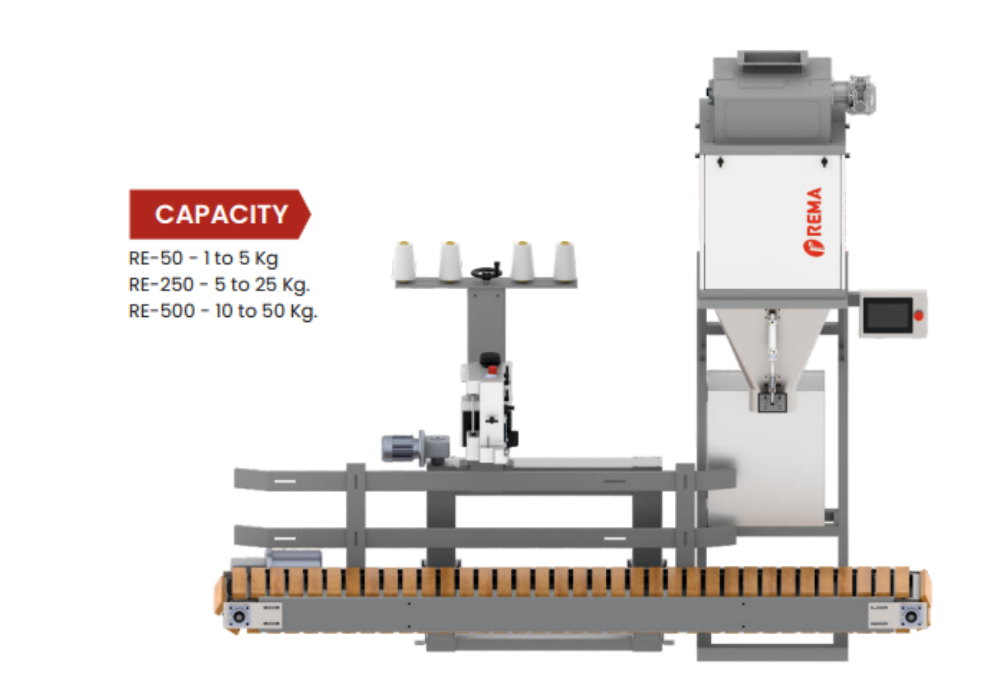

- Specifications:

| Model No: | RE-50, RE-250 & RE-500 |

|---|---|

| Hardware Belt Conveyer | 10 inch Touch Screen, Actuator, F301 Mainboard, Belt conveyor with reverse and forward direction, motorized height adjustmen |

| Data Export | Data export facility through USB |

| Communication | Rs485, Modbus TCP/IP |

| Feeding method | Feeding control by servo, pneumatic discharging |

| Controller | Touch Screen Bagging Controller, MAKE: REMA |

| Power Supply | AC 110 ~ 260V.50/60HZ. Approximate 200VA |

| Filling Mode | 3 Stage Feeding(Course, Moderately, fine) |

| Bag type | Open Mouth |

| Hopper Capacity | 100 KG |

| All Pneumatics | Make: Janatic India or CKD Japan |

| Switch Gears | Schneider |

| All Contact Parts | SS304 |

| Non-Contact parts | MS Powder Coated |

| Compressed Air | 6 Bar Continues (In Clients Scope) |

| Optional Accessories | Double thread - Auto thread cutter/ Heat sealing, Z type Bucket Elevator |

- our products

- Linear Type Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine

- Shuttle Type Modified Atmosphere Packing(MAP) Tray/Cup Sealing Machine

- Rotary Type Modified Atmosphere Packing (MAP) Tray/Cup Sealing Machine

- Semi Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine

- Fully Automatic VFFS High Speed Pouch Packing Machine

- Servo High Speed Automatic Bag Filling Machines

- Automatic Vacuum Packing Machine

- 2/4 head linear weighing filling machine

- Single Chamber Vacuum Packing Machine

- Double Chamber Vacuum Packing Machine

- Automatic Double Chamber Vacuum Packing Machine (Top Lid – Pneumatic Operated)

- Door Type Vertical Chamber Vacuum Packing Machine

- Vertical Double Chamber Vacuum Packing Machine

- Trolly Type Vertical Chamber Vacuum Packing Machine

- Nozzle Type Chamberless Vacuum Packing Machine

- Thermoforming Vacuum Packing Machine

- download brochure

Pulses Granules

Spices Granules

Seeds & Fertilizer