Rema Engineers’ Automatic Double Chamber Vacuum Packing Machine with a Pneumatic Operated Top Lid is an advanced solution for high-efficiency, high-volume packaging. Designed with two separate chambers, this machine allows for continuous operation: one chamber is used for vacuum packing, while the other is loaded or unloaded, greatly improving overall productivity. The pneumatic-operated top lid ensures smooth and precise sealing, offering a high level of automation and minimizing operator intervention. This feature makes the machine ideal for industries that require consistent and rapid packaging, such as food processing, pharmaceuticals, and more.

Automatic Double Chamber Vacuum Packing Machine

(Top Lid – Pneumatic Operated)

Home » Products & solutions » Automatic Double Chamber Vacuum Packing Machine (Top Lid – Pneumatic Operated)

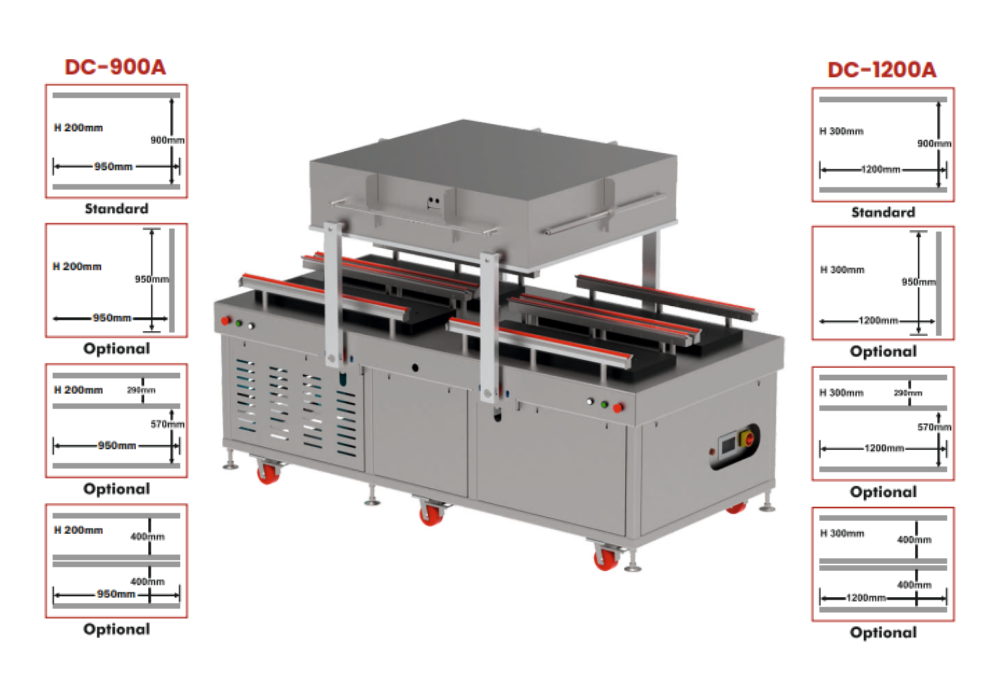

MODEL NO: DC-900A / MODEL NO: DC-1200A

The Automatic Double Chamber Vacuum Packing Machine is equipped with powerful vacuum pumps and adjustable sealing bars, ensuring superior performance and airtight sealing for a wide range of products. It helps preserve the freshness and shelf life of your products by protecting them from air, moisture, and contaminants. The user-friendly controls, along with the efficient pneumatic lid system, ensure smooth operation and a consistent, high-quality sealing process. This machine is built to deliver both reliability and speed, making it a perfect choice for businesses seeking to optimize their packaging processes while maintaining product integrity.

- Standard Features:

- Heavy duty automatic lid operated double chamber vacuum packing machine model to save loading - unloading time. PLC Based advance control panel with touch LCD display for adjustment of accurate vacuum & gas pressure.

- Design suitable for high productivity with high speed vacuum pump.

- Suitable for heavy micron & retort pouch accurate sealing.

- Easy to move castors wheels. Long lasting 10 mm heating elements for accurate sealing result.

- Stainless steel body, no sharp edges, use cast aluminium & other nonferrous materials to safe rust issue and easy cleaning.

- Vacuum & gas control by sensor for accurate level.

- BUSCH or BECKER (German Make) Vacuum Pump

- Standard Model Technical Specifications:

| MODEL NO. | DC-900A | DC-1200A |

|---|---|---|

| Pump Capacity | 150 m3/h - 300 m3/h | 300 m3/h - 500 m3/h |

| Sealing in MM (L x W) | 950 x 10 | 1200 x 10 |

| Machine Cycle | 15-40 Sec* | 15-40 Sec* |

| Machine Dimension in MM (L x W x H) | 2425 x 1255 x 1160 mm | 2290 x 1225 x 1150 |

| Machine Weight | 850 Kgs* | 1200 Kgs* |

| Power Supply | 415 V - 3 Ph - 50 Hz | 415 V - 3 Ph - 50 Hz |

| Power | 8 Kw | 10 Kw |

| Chamber LID | Pneumatic Operated | Pneumatic Operated |

| Digital Control | PLC HMI (Touch Screen) / 22 default program | |

| Sensor Control | Set percentage pressure gas vacuum and gas functions for accurate and constant packing result |

|

| Advanced Control System | Set percentage pressure or mbar/hPa/kpa for vacuum and gas function for accurate and constant packing results |

|

- our products

- Linear Type Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine

- Shuttle Type Modified Atmosphere Packing(MAP) Tray/Cup Sealing Machine

- Rotary Type Modified Atmosphere Packing (MAP) Tray/Cup Sealing Machine

- Semi Automatic Modified Atmosphere Packing (MAP) Tray/cup sealing machine

- Fully Automatic VFFS High Speed Pouch Packing Machine

- Servo High Speed Automatic Bag Filling Machines

- Automatic Vacuum Packing Machine

- 2/4 head linear weighing filling machine

- Single Chamber Vacuum Packing Machine

- Double Chamber Vacuum Packing Machine

- Automatic Double Chamber Vacuum Packing Machine (Top Lid – Pneumatic Operated)

- Door Type Vertical Chamber Vacuum Packing Machine

- Vertical Double Chamber Vacuum Packing Machine

- Trolly Type Vertical Chamber Vacuum Packing Machine

- Nozzle Type Chamberless Vacuum Packing Machine

- Thermoforming Vacuum Packing Machine

- download brochure